Glues Inspection

EcoRich Industrial is certified with ISO 9001:2015, demonstrating a professional quality management system that allows continuous optimization and improvement of every operational aspect. Moreover, our quality inspection laboratory and management personnel rigorously monitor all incoming and outgoing products, providing relevant inspection documents and composition analysis reports. This ensures quality assurance for all products received by our customers.

Testing Equipment

Abrasion Tester

Equipped with two sets of movable grinding heads, it enables simultaneous testing of two sets of samples (one experimental set and one control set)。

Solid/liquid Hydrometer

Designed according to ASTM D792, GB/T 1033, JIS-K-6268, ISO 2781 standards, it is capable of measuring the density of both solids and liquids

Dyne pen

According to DIN ISO 8296 specifications, it measures the surface tension of materials to confirm whether pretreatment is necessary for the adhesive material before dispensing at various points

Colorimeter

Through colorimetry measurements, it accurately confirms the real-time color of the adhesive material, allowing for the immediate detection of any discoloration or abnormalities.。

Durometer

It can test the softness and hardness performance of the adhesive material after curing, presenting the results according to Shore standards

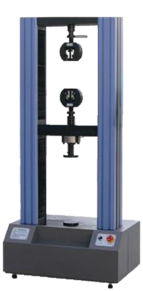

Universal Testing Machine

Connected through a computer, the material testing machine can be controlled to conduct various tests such as tensile (compression) strength, bending resistance, peel, and tensile (compression) holding, generating data reports.

Viscometer

It primarily tests the viscosity of various materials such as silicone gel, epoxy resin, and acrylic, serving as an important reference value to confirm the quality of adhesive materials.

Inspection documents

- COA:Raw material procurement involves requesting composition analysis reports from suppliers, and we proactively provide this information to our customers.

- Outsourced specialized composition analysis:When customers have concerns about the quality of received products, we can also send them to a professional third-party testing center for analysis

- REACH、RoSH:As a certified factory for electronic adhesive materials, our chemical substances comply with REACH and RoHS directives. Customers can request relevant reports at any time to meet the requirements of the electronics industry for chemical imports and exports.。

- Incoming、Outgoing Inspection:We prioritize the quality of all incoming and outgoing shipments, conducting inspections according to standard procedures, and providing digitized reports for customer review

- Exception handling process:When abnormalities occur, initiate the abnormal handling process, promptly dispose of non-conforming products, conduct an investigation, analyze the reasons, and formulate corrective measures to prevent recurrence.

繁體中文

繁體中文